Palm Oil Mill Effluent Treatment Process

Large and medium scale palm oil mills produce copious volumes of liquid waste from the sterilizer clarifying centrifuges and hydrocyclones.

Palm oil mill effluent treatment process. Agamuthu palm oil mill effluent e treatment and utilization. It was estimated that a processing plant with a capacity of 10 tons fresh fruit per hour would need a water treatment plant comparable to that required by a population of half a million inhabitants brezing 1986. Palm oil mill effluent pome waste treatment plants cater all raw effluent produced. Every year the number of palm oil mills increases rapidly thus increasing the capacity of fresh fruit bunch waste or effluent discharge.

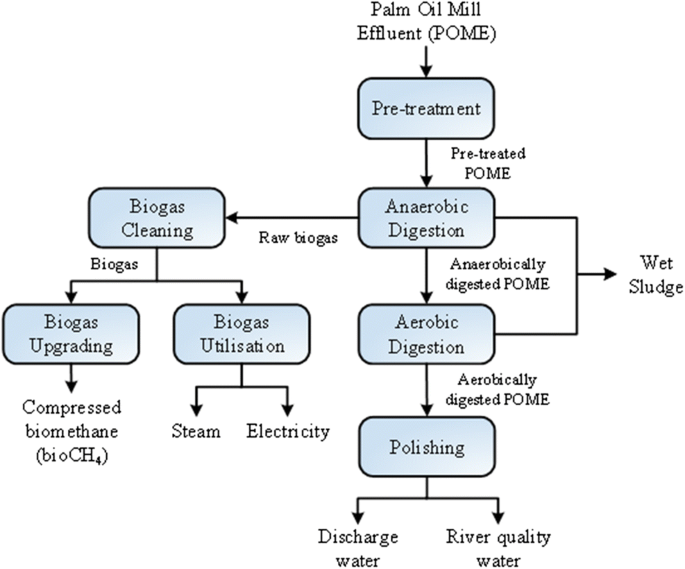

A review of methods proposed for its treatment tropical science 20 233 262 1978. Liquid waste treatment involves anaerobic fermentation followed by aerobic fermentation in large ponds until the effluent quality is suitable for discharge. A palm oil mill produces an average of 0 65 tons of raw palm oil mill effluent pome from every ton of ffb processed. Based on the data from the malaysian palm oil board in 2012 malaysia produced 99 85 million tons of fresh fruit bunch ffb per year.

This effluent must be treated before discharge to avoid serious environmental pollution. In recent decades malaysia has been known as one of the world s leading producers and exporters of palm oil products. Effluent treatment the palm oil process uses water to separate the oil from sludge and solids in a tank. After the removal of oil the waste water effluent is discharged from the mill.

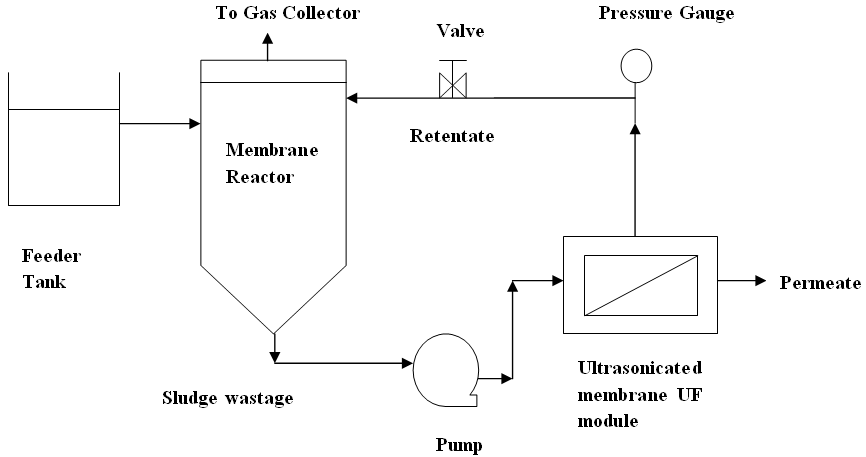

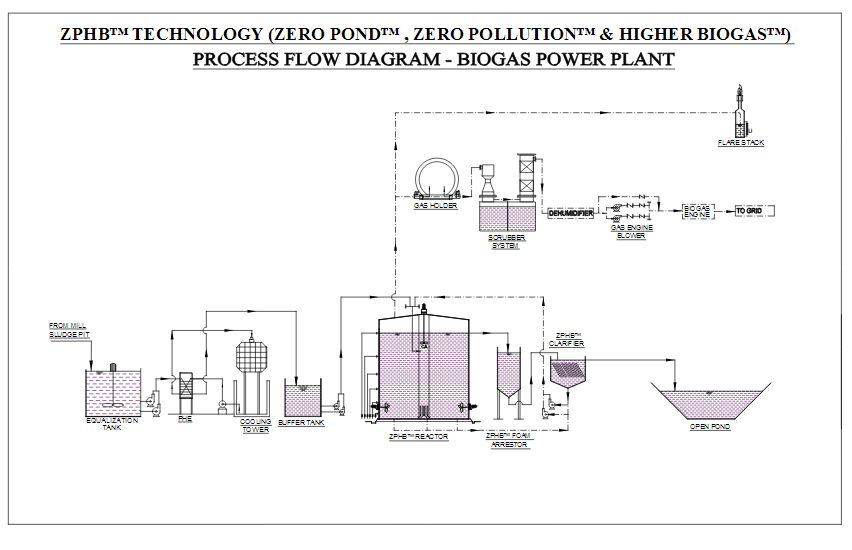

In 2003 a total of 2 106 956 tonnes of ffb were processed resulting in 1 369 521 tonnes of pome being produced. The application of membrane separation technology coupled with adsorption treatment pre treatment can be effective means of treating palm oil mill effluent pome the pre treatment process was done by stirring the raw palm oil mill effluent pome with 0 20 g l of palm kernel shell based activated carbon pks ac in 35 94 min with stirring speed 39 82 rpm and able to reduce 71 26 of. Biogas generation from palm oil mill effluent treatment plant is becoming the future trend for the palm oil millers. Davis palm oil mill effluent.

Pome is the main cause of environmental pollution due to its high acidity high biological oxygen demand bod and chemical oxygen demand cod. Edewor a comparison of treatment methods for palm oil mill effluent pome wastes journal of chemical technology biotechnology 36. This effluent contains particles of vegetable matter and needs to be treated before discharge to the environment. Therefore the efficient treatment of biogas producing process effluent is equally important to minimize the detrimental effect towards human and environment.